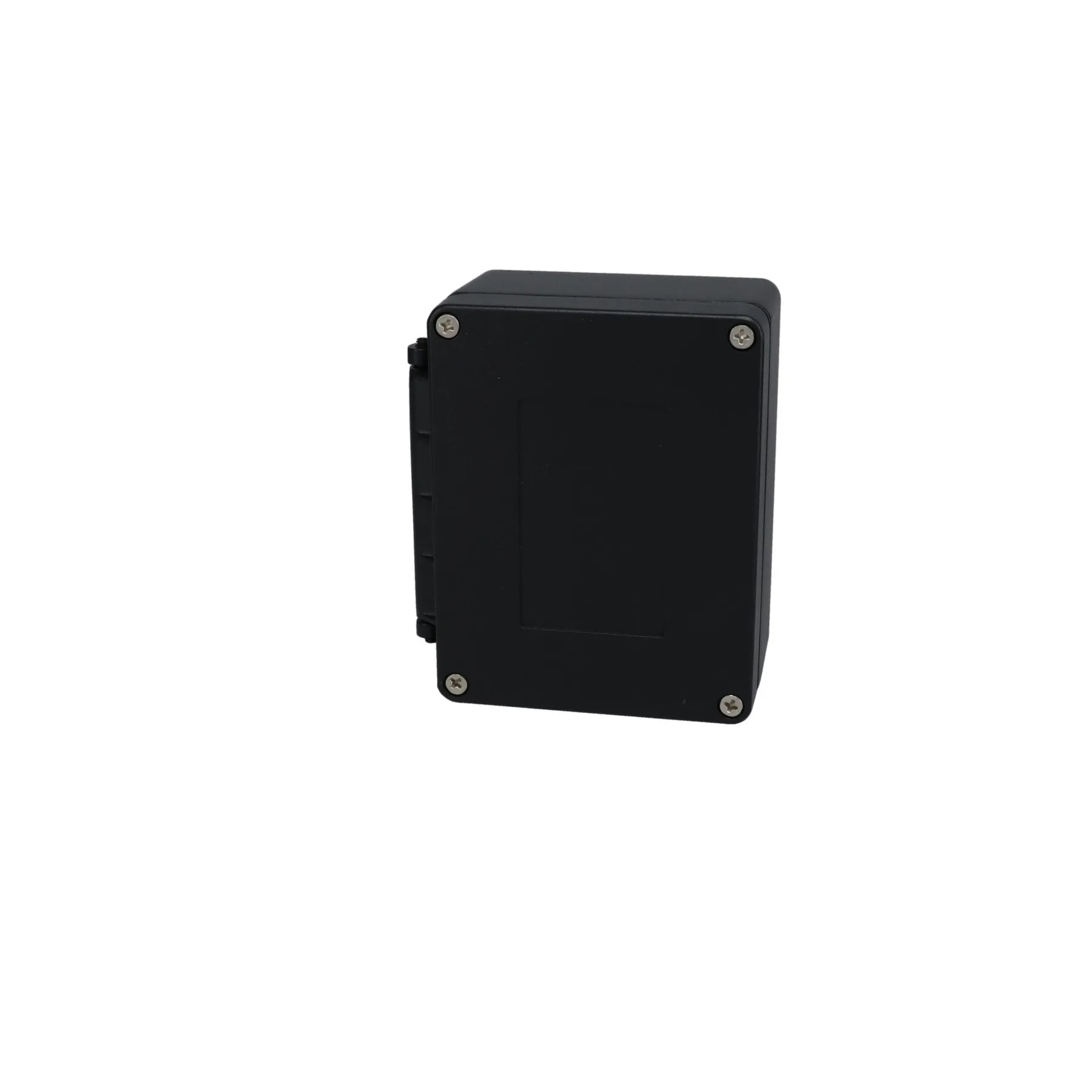

What is a Diecast Aluminum Enclosure?

A diecast aluminum enclosure is a protective housing made through the die-casting process, using aluminum alloys. These enclosures are widely used in various industries to safeguard electronic components, electrical devices, and other sensitive equipment from environmental factors such as moisture, dust, and physical impact. Their robustness and versatility make them ideal for applications requiring durability and reliability. The manufacturing process involves injecting molten aluminum under high pressure into a mold (die), which creates intricate shapes with high precision. This method allows for the production of complex designs that would be difficult or impossible to achieve with other manufacturing techniques, making diecast aluminum enclosures a preferred choice for many applications.

Materials Used in Diecast Aluminum Enclosures

The primary material for diecast aluminum enclosures is, unsurprisingly, aluminum. However, it’s not pure aluminum but rather a range of aluminum alloys, each offering different properties suited to specific needs. These alloys are carefully selected to provide the best balance of strength, corrosion resistance, and thermal conductivity. Other materials may include components such as gaskets, seals, and fasteners, used to enhance protection and functionality. The choice of materials significantly impacts the enclosure’s performance and suitability for its intended environment. The right combination of materials is crucial for ensuring the longevity and effectiveness of the enclosure in safeguarding the valuable components it houses.

Aluminum Alloys for Diecasting

Several aluminum alloys are commonly used in diecasting, each with distinct characteristics. Common alloys include ADC12, A380, and A383. ADC12 is popular for its good balance of mechanical properties, castability, and corrosion resistance, making it suitable for general-purpose applications. A380 offers excellent die-casting characteristics and is known for its good strength and ability to be easily machined. A383 is similar to A380 but often contains slightly higher silicon content, which improves its fluidity during the casting process, making it suitable for complex designs. The choice of alloy depends on the specific requirements of the enclosure, including the operating environment, mechanical stress, and desired lifespan. Different alloys provide different properties like thermal conductivity, which is essential for heat dissipation in electronic devices. Selecting the appropriate alloy is vital for the enclosure’s performance and durability.

Manufacturing Process for Diecast Aluminum Enclosures

The manufacturing of diecast aluminum enclosures is a sophisticated process involving several key stages. The process starts with designing the enclosure and creating a mold (die) that precisely matches the desired shape and dimensions. The die is typically made from high-strength steel. The molten aluminum alloy is then injected into the die under high pressure. This pressure forces the metal to fill the intricate details of the mold, ensuring dimensional accuracy and a smooth surface finish. After the aluminum solidifies, the die is opened, and the enclosure is ejected. The final step involves trimming excess material, performing any necessary machining, and applying surface finishes such as powder coating or anodizing. The entire process requires precise control and quality checks at each stage to ensure that the finished product meets the required specifications and performance standards.

Die Casting Process

The die-casting process itself is a critical part of manufacturing diecast aluminum enclosures. There are two primary types of die-casting: high-pressure die casting (HPDC) and low-pressure die casting (LPDC). HPDC is the most common method for producing these enclosures because of its speed and ability to produce complex shapes. In HPDC, molten aluminum is forced into the die under high pressure, typically ranging from 1,500 to 30,000 psi. This high pressure ensures that the metal completely fills the mold cavity, producing parts with high dimensional accuracy and a smooth surface finish. LPDC uses lower pressure, generally around 15 to 20 psi, and is often used for larger or more intricate parts where a slower fill rate is desired. This method provides better control over the metal flow and can reduce porosity in the casting. The choice between HPDC and LPDC depends on the complexity of the design, the required production volume, and the desired mechanical properties of the final product.

Surface Finishing Techniques

Surface finishing techniques are essential for enhancing the performance, appearance, and durability of diecast aluminum enclosures. Common techniques include powder coating, anodizing, and painting. Powder coating involves applying a dry powder to the surface of the enclosure and then baking it to create a durable, uniform finish. This method provides excellent corrosion resistance and can be applied in various colors. Anodizing is an electrochemical process that converts the aluminum surface into a decorative, durable, corrosion-resistant anodic oxide finish. Anodizing increases the thickness of the natural oxide layer, providing enhanced protection and can also accept dyes for colored finishes. Painting offers a cost-effective way to add color and protection. The choice of finish depends on the intended application, the required level of protection, and aesthetic considerations. Proper surface treatment ensures that the enclosure is well-protected and aesthetically pleasing, extending its service life and improving its performance.

Design Considerations for Diecast Aluminum Enclosures

Designing a diecast aluminum enclosure involves careful consideration of several factors to ensure its functionality, manufacturability, and cost-effectiveness. Key design elements include the overall shape and size, the thickness of the walls, and the placement of features such as mounting holes, vents, and connectors. Designers must also consider the potential for thermal management, such as the inclusion of heat sinks or ventilation slots, to dissipate heat generated by internal components. The design should account for the die-casting process, with considerations for draft angles and the optimal placement of gates and runners to facilitate metal flow during casting. The design phase often involves using CAD software to create 3D models and simulations to optimize the enclosure’s design and ensure it meets the required performance specifications. Collaboration between designers, manufacturers, and end-users is crucial for creating a successful diecast aluminum enclosure.

Size and Shape

The size and shape of the diecast aluminum enclosure are critical design elements that directly impact its functionality, performance, and aesthetics. The size must accommodate the internal components, such as circuit boards, power supplies, and connectors, while also providing sufficient space for ventilation and heat dissipation. The shape can be customized to meet specific requirements, ranging from simple rectangular boxes to complex, contoured designs. Rounded corners and smooth surfaces often enhance the enclosure’s aesthetics and reduce the risk of sharp edges. The chosen shape and size significantly affect the enclosure’s ability to withstand environmental factors, such as impact and water ingress. The design must consider the intended application and the overall user experience, balancing functionality with visual appeal.

Sealing and Protection

Sealing and protection are paramount considerations in the design of diecast aluminum enclosures, ensuring the safety and reliability of the internal components. Enclosures are designed to provide protection against various environmental factors, including dust, moisture, and electromagnetic interference (EMI). Sealing can be achieved through the use of gaskets, O-rings, and other sealing materials, which are strategically placed to create a barrier against external elements. The enclosure’s design may incorporate features like overlapping joints, recessed areas for sealing, and specialized connectors to enhance the level of protection. Additionally, the materials used in the enclosure and the finishing techniques applied can provide further protection against corrosion and environmental degradation. Properly sealed and protected enclosures are critical for ensuring that the internal components operate safely and effectively, extending their lifespan and minimizing the risk of failure.

Thermal Management

Thermal management is a crucial aspect of designing diecast aluminum enclosures, particularly for electronic devices that generate heat. The enclosure must effectively dissipate heat to prevent the internal components from overheating, which can lead to reduced performance or failure. Aluminum’s high thermal conductivity makes it an excellent material for heat dissipation. Design features such as heat sinks, which increase the surface area available for heat transfer, can be integrated into the enclosure. Ventilation slots and fan mounts can facilitate airflow, further aiding in cooling. The design may also incorporate thermal pads or other materials to improve heat transfer between the components and the enclosure. Effective thermal management is essential for maintaining the reliability and longevity of electronic devices, ensuring that they operate within their specified temperature ranges. Careful consideration of these thermal properties helps optimize the design for heat dissipation.

Applications of Diecast Aluminum Enclosures

Diecast aluminum enclosures are used across a wide range of industries due to their robustness, versatility, and ability to protect sensitive components. Their durability and shielding capabilities make them well-suited for demanding environments. From protecting delicate electronics to ensuring the reliability of automotive systems, these enclosures provide essential functionality. The following are some of the most common applications. The specific requirements of each application influence the design, material selection, and finishing techniques employed, ensuring that the enclosure meets the performance and environmental demands of the specific industry.

Electronics

In the electronics industry, diecast aluminum enclosures are widely used to house and protect electronic components, such as circuit boards, power supplies, and control modules. They are often found in industrial control systems, telecommunications equipment, and consumer electronics devices. The enclosures provide protection from physical damage, electromagnetic interference (EMI), and environmental factors like moisture and dust. The ability to incorporate heat sinks and ventilation features makes them suitable for applications where heat dissipation is a critical concern. The precision and durability of diecast aluminum enclosures ensure that sensitive electronics operate reliably and efficiently, regardless of the operating environment. Their versatility allows for customization to meet specific size, shape, and performance requirements.

Automotive Industry

The automotive industry relies heavily on diecast aluminum enclosures to protect critical electronic and electrical components in vehicles. These enclosures are used to house engine control units (ECUs), anti-lock braking systems (ABS), transmission control units (TCUs), and other essential modules. The enclosures must withstand harsh conditions, including extreme temperatures, vibrations, and exposure to chemicals and moisture. Diecast aluminum enclosures offer excellent mechanical strength, corrosion resistance, and thermal management capabilities, making them ideal for automotive applications. The ability to achieve complex designs and incorporate features such as sealing and EMI shielding further enhances their suitability. The reliability of these enclosures is crucial for ensuring the safety and performance of modern vehicles.

Telecommunications

In the telecommunications sector, diecast aluminum enclosures are essential for protecting sensitive networking equipment, such as routers, switches, and base stations. These enclosures are often used outdoors, where they must withstand exposure to the elements, including rain, snow, and extreme temperatures. The enclosures provide robust protection against physical damage, environmental hazards, and electromagnetic interference. They also contribute to effective heat dissipation, which is critical for maintaining the performance and reliability of the equipment. The enclosures are designed to accommodate various connector types, mounting options, and cooling solutions. Diecast aluminum enclosures’ durability and adaptability make them a key component in ensuring reliable communication infrastructure.

Choosing the Right Diecast Aluminum Enclosure

Selecting the appropriate diecast aluminum enclosure involves careful consideration of several factors to ensure it meets the specific requirements of the application. Key considerations include the size and shape of the enclosure, the internal space needed to accommodate components, and the required level of protection against environmental factors such as water, dust, and EMI. The operating temperature range, potential for thermal management, and required durability must also be assessed. The choice of aluminum alloy and surface finishing techniques should be based on the intended environment and the desired aesthetic appearance. Consulting with an experienced manufacturer and evaluating available options is crucial for making an informed decision and selecting an enclosure that optimizes performance, reliability, and cost-effectiveness.

Factors to Consider

Several factors should be considered when choosing a diecast aluminum enclosure. Firstly, the size and shape of the enclosure must accommodate all internal components and provide adequate space for ventilation and heat dissipation. Secondly, the environmental conditions to which the enclosure will be exposed must be assessed. This includes temperature fluctuations, exposure to moisture, dust, and the potential for physical impact. Thirdly, the required level of protection against EMI should be determined. Fourthly, the mechanical strength and durability of the enclosure must be evaluated, considering factors such as vibration resistance and the potential for corrosion. Lastly, the cost, availability, and lead time of the enclosure should be considered. These factors help ensure the best selection for the application.

Cost Analysis

Performing a cost analysis is essential when choosing a diecast aluminum enclosure to ensure the best value for the application. The initial cost includes the price of the enclosure itself, which varies depending on the size, complexity, and finish. Additionally, consider the tooling costs, especially for custom designs. The total cost should also include any associated expenses, such as machining, assembly, and testing. In the long term, factors such as the enclosure’s lifespan, maintenance requirements, and potential for component failures should be considered. A thorough cost analysis ensures that the chosen enclosure offers the best balance of performance, reliability, and affordability over its intended lifetime. Comparison of different suppliers and enclosure options is advisable to determine the most cost-effective solution.

Where to Buy Diecast Aluminum Enclosures

Diecast aluminum enclosures can be purchased from various sources, including specialized manufacturers, distributors, and online retailers. When choosing a supplier, consider the manufacturer’s experience, reputation, and ability to meet your specific requirements. Distributors often offer a wide range of standard enclosures from multiple manufacturers, providing a convenient option for selecting off-the-shelf solutions. Online retailers offer a wide selection of enclosures, allowing for easy comparison and ordering. When selecting a supplier, evaluate factors such as the availability of technical support, customization options, and lead times. Verify that the supplier can provide enclosures that meet the required certifications and quality standards. Choosing a reputable supplier ensures that you receive a high-quality enclosure that meets the specifications of your application.